Bathroom

Our bathroom products are made using advanced technologies proven to be successfull used all over the world, guaranteeing their reliability, functionality and stunning design.

We are constantly developing to meet the expectations of the most demanding customers.

The offer of WK Composites includes:

-

Baths

-

Sinks

-

Hot Tubs

-

Disability Aids

Our Anti Slip shower trays are made of composite and a specially developed integrated anti-slip layer on the surface of the shower tray.

We decided that the anti-slip part should be made of the same material as the rest of the shower tray surface.

During long-term tests, it was possible to create an anti-slip structure that is an integral part of the mould.

The product is made of a carefully prepared mould, which guarantees repeatability and longevity of the integrated anti-slip products.

The anti-slip surface is built during production and is made of composite as well as the rest of the shower tray.

As a result, it does not wear out even with intensive use and guarantees high safety when using the shower for years.

The non-slip surface is flat and almost invisible on the surface of the shower tray. It is very easy to keep clean,

it is resistant to various types of chemicals and temperature differences without affecting its anti-slip properties.

Most anti-slip shower trays on the market are coated with anti-slip liquids - It is a better solution than none, but it is short-term.

Anti-slip coat do not have the same chemical and temperature resistance as products made of composite materials - in this case the fiberglass is used in the production of boats and luxury yachts.

It is worth mentioning that covering the shower tray with liquids is done manually, it will be applied in some places thick or thin - it gives different protective values on the shower.

As we mentioned, our shower trays have an anti-slip surface that is copied from the mould during the production process.

This gives us the opportunity to maintain the same anti-slip values on the entire surface of the anti-slip shower trays.

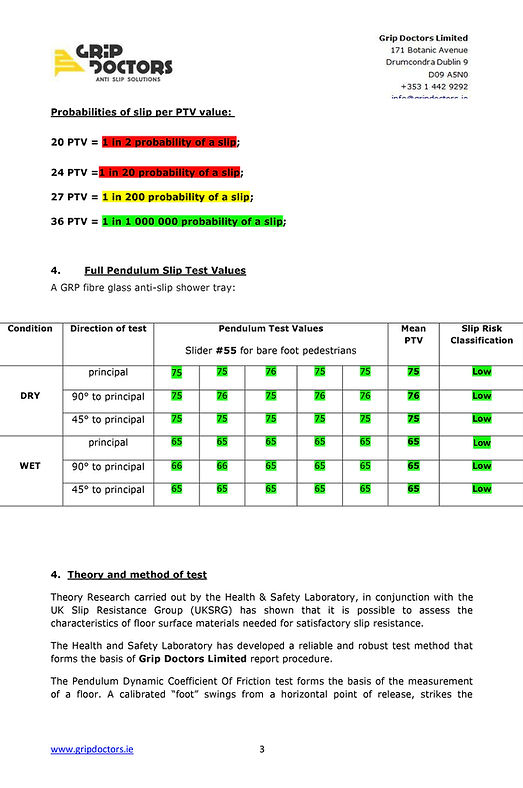

After many tests, we obtained the expected result of an anti-slip shower tray in accordance with BS7976 standards confirmed by the Pendulum Test report.

Reading 75 PTV dry and 65 PTV wet, barefoot tested with No.55 slider, guarantees low slip and an easy-to-clean, hygienic surface.

The smooth but non-slip surface of the shower tray does not affect the aesthetics of the product.

It provides maximum comfort and safety while bathing.

Anti-slip shower trays.

Pendulum Slip Test Report

Pendulum Slip Test - 65 PTV ON WET

Anti-Slip Walk-in Shower Tray

WHAT’S IT MADE OF ?

The product is entirely made of composites used in the production of Yachts, Swimming Pools

and GRP Water Tanks

The outer surface is covered with two layers of antibacterial gel - It is easy to clean and resistant

to chemical cleaning agents.

Then two layers of glass fiber (GRP, FRP) are applied with a high-quality polymer resin - It has extremely high physical resistance, high temperatures and does not corrode.

A Resin Infused Particle Board is placed on the GRP - To strengthen the product and facilitate

the installation of the shower door.

The Resin Infused Particle Board is covered with a layer of glass fiber which is gel-coated for lifetime water resistance and moisture.